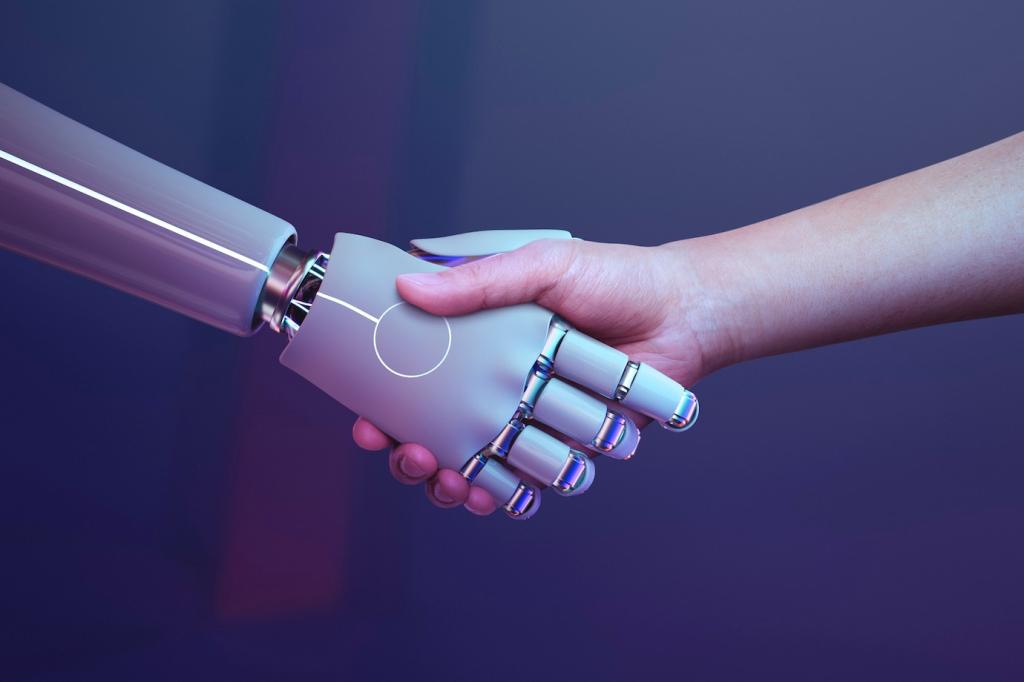

AI-Driven Transformation in Global Supply Chains

AI-driven transformation is revolutionizing global supply chains, ushering in a new era of intelligent automation, predictive analytics, and enhanced decision-making capabilities. This evolution not only increases efficiency but also delivers greater resilience and agility in response to global challenges. From optimizing inventory to predicting market demand, AI is reimagining traditional processes and empowering organizations to stay competitive in an interconnected world. This page explores how AI technologies are reshaping every facet of supply chain management, highlighting the prominent benefits, challenges, and innovations that define the modern landscape.

The Rise of Artificial Intelligence in Supply Chains

Automation of Routine Tasks

One of the most significant impacts of AI in supply chains is the automation of repetitive, time-consuming tasks. From order processing to shipment tracking, AI-powered systems can quickly handle large volumes of data with minimal human intervention, dramatically reducing operational costs and errors. This efficiency not only streamlines internal workflows but also allows staff to focus on value-added activities. As intelligent automation expands, companies experience faster turnaround times and increased accuracy, making their supply chains more adaptive to ever-changing demands.

Enhanced Data Integration

AI excels at merging disparate sources of data into a cohesive and actionable format. Supply chains generate vast amounts of information across procurement, manufacturing, and distribution functions. Artificial intelligence systems analyze, interpret, and synthesize this data, providing a unified view across the entire supply network. Improved data integration enables real-time decision-making, responsiveness to disruptions, and a better understanding of the interplay between various supply chain elements, directly empowering leaders to make informed choices.

Predictive Analytics Adoption

Predictive analytics, enabled by advanced AI algorithms, is transforming supply chains from reactive to proactive ecosystems. Companies can anticipate potential disruptions, forecast demand with greater precision, and optimize inventory levels. Such capabilities help mitigate risks, reduce wastage, and ensure that goods flow efficiently from suppliers to customers. As organizations harness the predictive power of AI, they achieve greater certainty in their planning processes, fostering stronger resilience against an unpredictable global landscape.

Intelligent Demand Forecasting and Planning

AI-driven systems are exceptionally adept at recognizing patterns in market behavior, allowing companies to anticipate sudden shifts in demand. Machine learning models process a multitude of influencing factors like seasonality, geopolitical events, and emerging consumer preferences that traditional forecasting methods might overlook. This nuanced analysis enables supply chains to adapt production schedules or inventory strategies, positioning organizations to capture new opportunities and avoid costly miscalculations.

End-to-End Shipment Monitoring

AI systems can integrate with IoT devices and advanced tracking technologies, providing granular, real-time updates on the status and location of products as they move through the supply chain. Immediate alerts about delays, route changes, or adverse conditions enable logistics managers to take swift corrective actions. Enhanced shipment visibility reduces uncertainty, ensures timely deliveries, and builds trust with partners and customers alike.

Enhancing Supplier Transparency

Supplier relationships are critical yet often opaque elements of the supply chain. Artificial intelligence solutions analyze supplier performance metrics, audit logs, and compliance records to provide greater transparency. With a clear understanding of supplier reliability and risk factors, companies can make more informed decisions about sourcing strategies and contingency planning. This transparency helps foster more collaborative, accountable partnerships throughout the network.

Proactive Issue Resolution

When disruptions or anomalies occur, AI-driven platforms can instantly analyze causes and identify the best corrective measures. By proactively addressing potential issues—be it a transportation delay, equipment malfunction, or sudden spike in demand—supply chains minimize disruptions and preserve service levels. Real-time issue identification and escalation supported by artificial intelligence ensures operations remain resilient, even amidst unexpected challenges.

Previous

Next

AI-powered analytics assess the carbon footprint of every supply chain touchpoint, from raw material sourcing to final delivery. By modeling transportation routes, production methods, and packaging choices, AI identifies opportunities to reduce emissions. Implementation of greener practices is automated where possible, ensuring ongoing adherence to sustainability goals. This data-driven approach enables companies to not only comply with regulations but also meet the expectations of environmentally conscious consumers.

Innovations in Logistics and Distribution

Autonomous Transportation

Self-driving trucks, drones, and robotic delivery vehicles are moving from experimental to operational stages, thanks to AI. These technologies promise faster, more reliable transportation by minimizing human error and optimizing operations 24/7. Integration with supply chain management platforms allows for live re-routing and load balancing, ensuring shipments reach their destination on time, even under rapidly changing conditions.

Smart Warehouse Automation

AI-powered robots, automated picking systems, and intelligent storage solutions are transforming traditional warehouses into facilities of the future. These technologies coordinate to maximize space utilization, accelerate order fulfillment, and reduce labor costs. With real-time inventory tracking and predictive maintenance, smart warehouses streamline logistics and contribute to an integrated, efficient distribution network that scales effortlessly with demand.

Intelligent Route Optimization

AI analyzes countless variables—traffic patterns, weather, customer preferences, regulatory restrictions—to determine the most efficient delivery routes. By dynamically recalibrating delivery schedules and assigning transport assets where they’re needed most, AI-driven route optimization ensures on-time, cost-effective shipment. This not only benefits logistics providers but also enhances the customer experience by enabling accurate tracking and reliable estimated delivery windows.

Addressing Data Silos and Integrity

Effective AI deployment requires high-quality, integrated data from all facets of the supply chain. Many organizations struggle with siloed systems, inconsistent data formats, and incomplete information. Establishing robust data governance frameworks, cleaning legacy datasets, and integrating diverse platforms are critical steps. As data integrity improves, AI delivers more reliable insights and drives superior outcomes.

Change Management and Workforce Upskilling

Introducing AI technologies demands a fundamental shift in organizational culture and employee competencies. Resistance to change and skills gaps can stall transformation efforts. Comprehensive change management initiatives, transparent communication, and ongoing training programs are necessary to equip staff with the know-how to leverage AI tools. Empowered teams are more likely to embrace innovation and contribute to long-term success in an AI-enabled supply chain.

Ethical and Regulatory Considerations

As AI becomes more prevalent, ensuring ethical use, data privacy, and regulatory compliance is increasingly complex. Organizations must develop clear guidelines and adopt technologies that are transparent and explainable. Ongoing monitoring and adaptation to evolving legal requirements are essential. Proactively addressing these issues builds trust with stakeholders and ensures sustainable, responsible growth on a global scale.